Shuangliang Energy Conservation: Innovation-driven, transforming towards service-oriented manufacturing

You might not expect that the cooling, heating, and domestic hot water for the entertainment facilities, public buildings, and hotels in the Shanghai Disney Resort are provided by a core energy-saving system from a Jiangyin company across the river, which is Shuangliang Energy Saving.

At the Disney Energy Center, Shuangliang's flue gas hot water lithium bromide unit is configured one-to-one with the gas internal combustion engine generator set, absorbing the waste heat from the internal combustion engine's flue gas and cylinder cooling water, achieving energy cascading utilization and efficient use, raising the overall energy comprehensive utilization rate to 85.9%. Compared to traditional theme parks, this can reduce carbon dioxide emissions by about 75,000 tons annually.

Shuangliang started with a high point, showing extraordinary talent right from the start. As early as 1985, Shuangliang produced China's first lithium bromide chiller with independent intellectual property rights; in 1992, the company was responsible for drafting the first industry standard in the field of lithium bromide absorption in China; in 1994, Shuangliang's enterprise technology center was recognized as a national-level enterprise technology center...

While solidifying its corporate foundation, Shuangliang has also been exploring new markets. To meet the diverse energy needs of customers, Shuangliang has successively developed hot water lithium bromide units, direct-fired lithium bromide units, and flue gas lithium bromide units, forming a complete product series, thus establishing its leading position in China's lithium bromide industry.

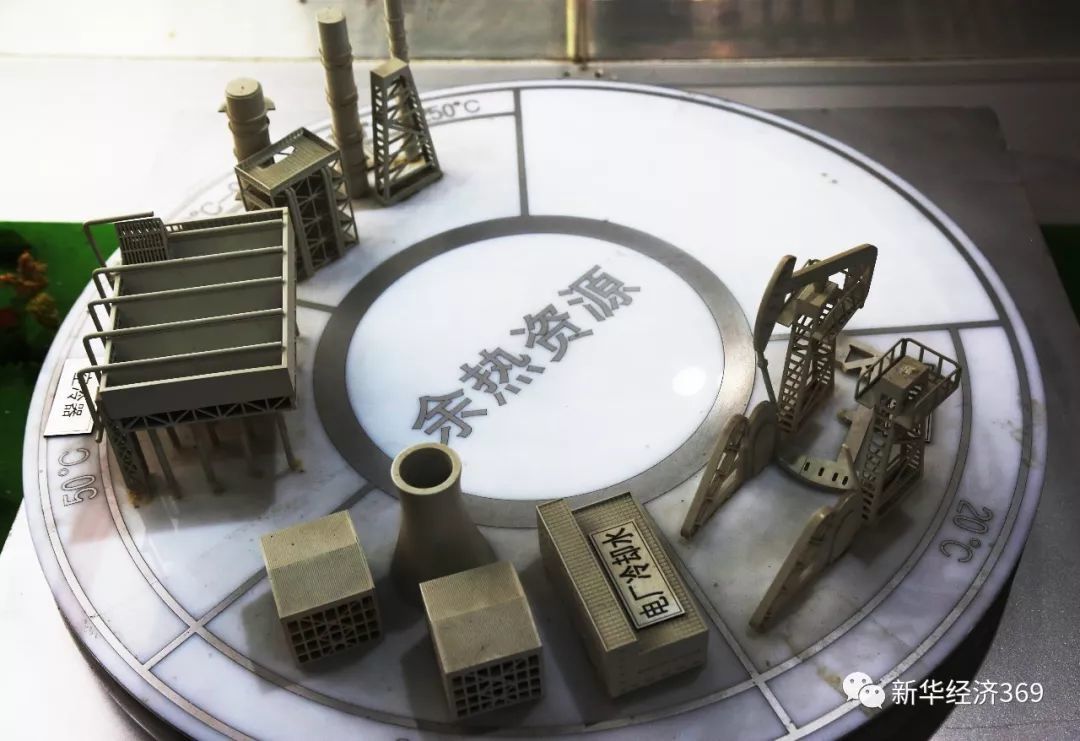

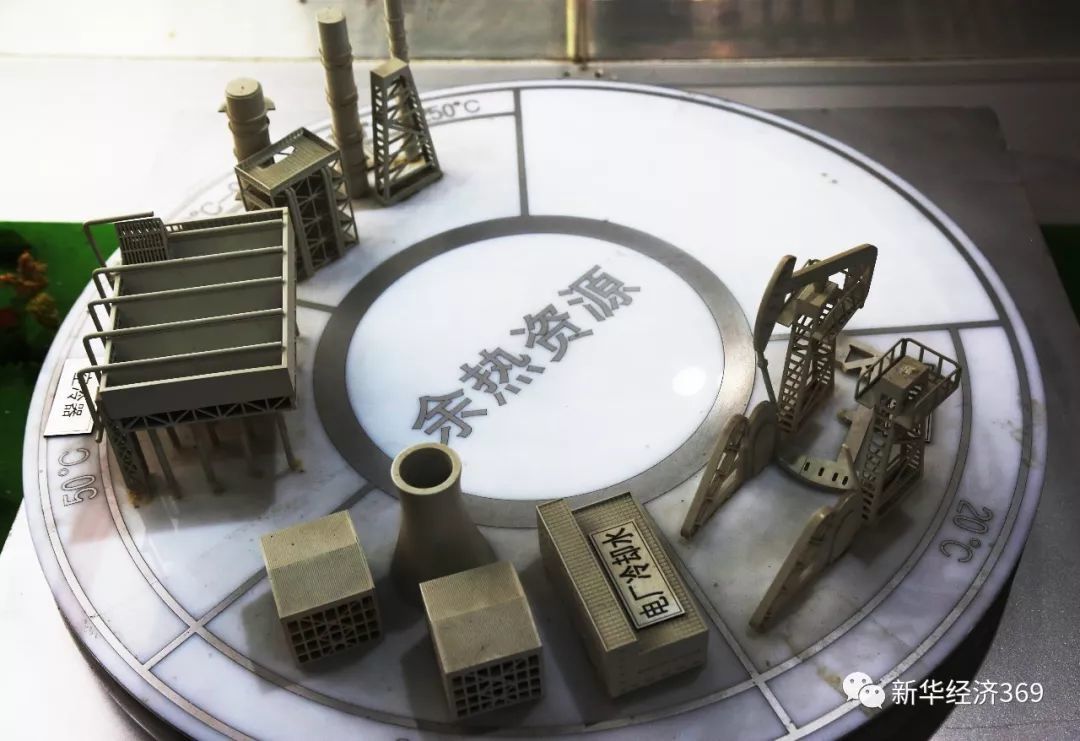

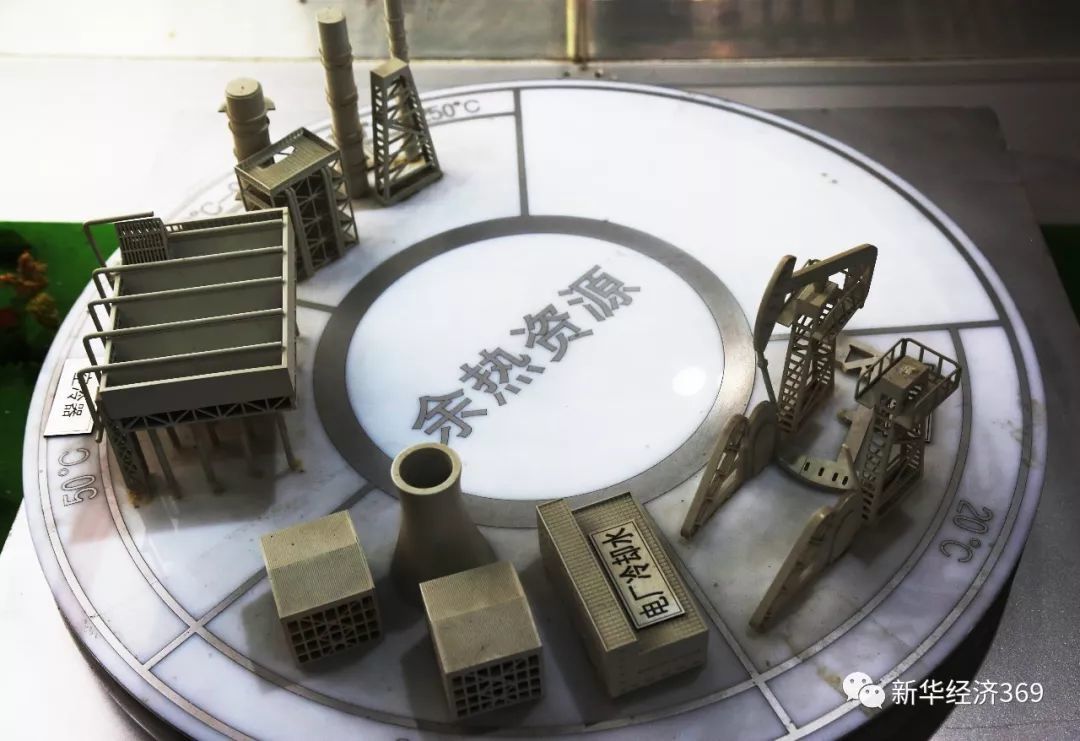

In fact, the strongest vitality and competitiveness of lithium bromide absorption refrigeration technology lies in waste heat utilization. "Shuangliang Energy Saving's general manager Liu Zhenyu recalled that at a time when the large central air conditioning industry was thriving, Shuangliang decisively ventured into the energy-saving and environmental protection field, exploring new 'blue oceans.'"

Starting in 1995, Shuangliang applied its core technology - vacuum heat exchange - to lithium bromide absorption heat pump units, successfully extending the product's application in the waste heat utilization market, such as the waste heat recovery system at Shanxi Guodian Datong Second Power Plant and the China National Offshore Oil Corporation's direct-fired tail water heating project... Currently, Shuangliang's waste heat utilization systems are widely used in nine major industries, including petroleum and petrochemicals, steel smelting, coking, and textile chemical fibers, with over 30,000 users in the waste heat utilization field.

Wuhan International Expo Center, China National Convention Center, Beijing South Railway Station, Xi'an South China City, Milan Linate International Airport in Italy... Shuangliang has successfully put into operation over 100 cold and heat supply projects globally.Heat and powerCombined supply projects, providing 200 sets of multi-coldHeat and powercombined supply system solutions.

Today, in the domestic market, Shuangliang's product market share is about 40%; in overseas markets, products are exported to more than 50 countries and regions, including Germany, Japan, Russia, the United States, and Argentina, and have developed into partners with nearly 300 Fortune 500 companies, gradually forming an international Shuangliang global map.

Previous Page: