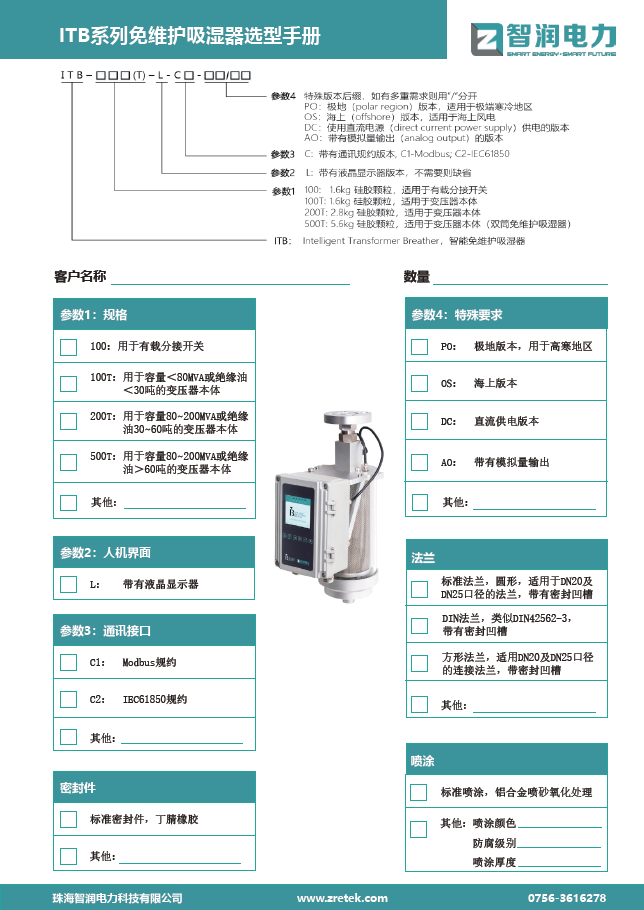

ITB-200T-L

ITB-200T-L Smart Maintenance-Free Dehumidifier

Smart maintenance-free dehumidifier

Key words:

Classification:

Weight:

13 kilogram

Delivery date:

Download Instructions:

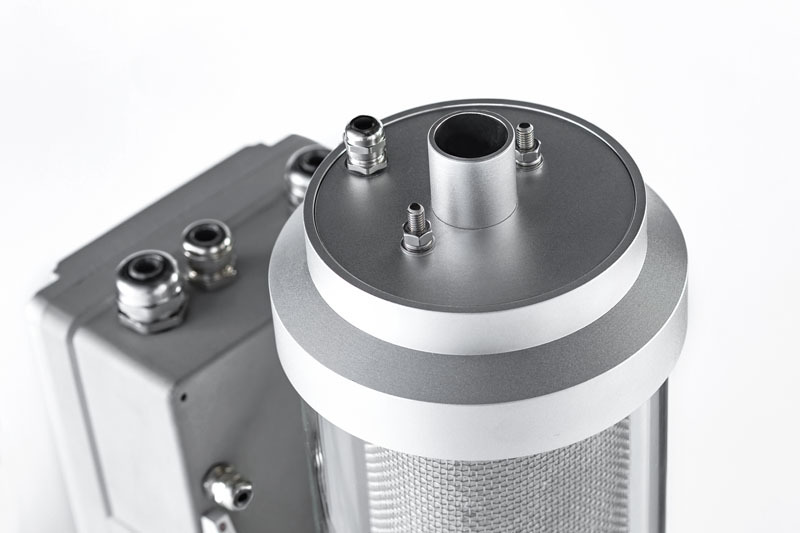

The ITB intelligent maintenance-free dehumidifier consists of several parts including a silicone chamber, heating device, filtering device, and intelligent controller. Humid air enters the device through the metal filter screen at the bottom of the ITB maintenance-free dehumidifier, which filters dust, sand, and other particles from the air. The filtered air passes through the silicone chamber in the dehumidifier for dehydration, and the dehumidified air enters the transformer through the pipeline in the oil cushion.

The ITB intelligent maintenance-free dehumidifier is equipped with a temperature and humidity sensor to measure the humidity of the air entering the transformer. When the measured humidity exceeds the set value and the transformer is in exhalation mode, the heating element installed in the drying chamber will automatically dry the silicone particles. The water vapor generated during the silicone drying process condenses on the glass outer wall of the maintenance-free dehumidifier, and the condensate is discharged through the metal filter screen, which also helps to clean the metal filter screen.

The ITB intelligent maintenance-free dehumidifier can upload the device's operating status and the temperature and humidity data of the transformer breathing pipeline to the background monitoring system via communication protocol for real-time monitoring, data storage, analysis, and mining functions.

The ITB intelligent maintenance-free dehumidifier eliminates the need for silicone replacement and cleaning of the oil cup, reducing labor costs and avoiding safety hazards caused by blocked breathing passages. At the same time, the ITB intelligent maintenance-free dehumidifier can also upload the device's operating status and temperature and humidity data of the breathing passage to the computer monitoring system, making it particularly suitable for centralized control and unmanned operation modes in substations. It effectively improves the intelligence level of the equipment and is beneficial for the safe operation of transformers.

- Equipped with ITB-Tool monitoring software for real-time monitoring, convenient and fast. This software can display the temperature and humidity values detected by ITB in real-time and control the operation of the silicone heater and filter heater.

- Core components are made of imported industrial-grade components.

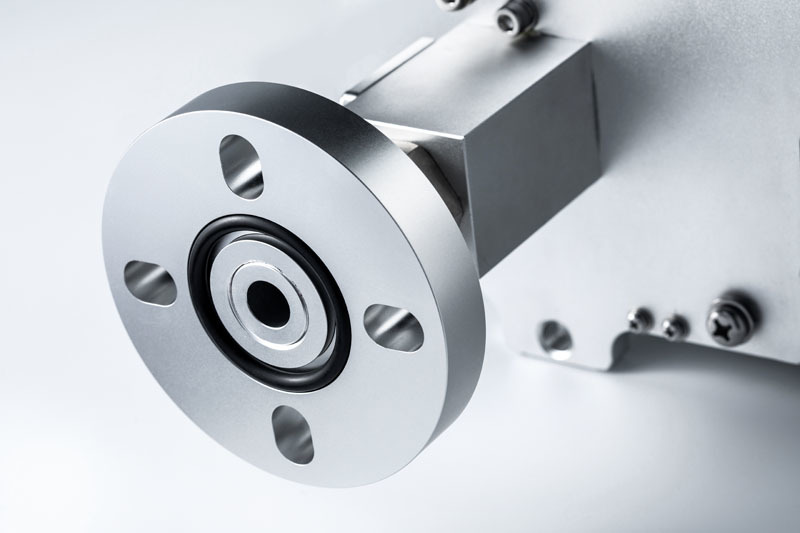

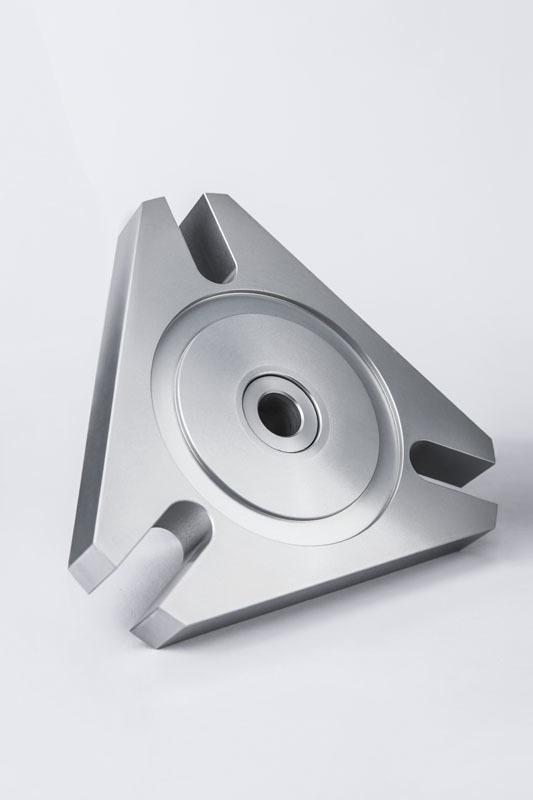

- All components are corrosion-resistant and resistant to high and low temperatures; metal parts are made of stainless steel or anodized aluminum alloy materials.

- IP65 protection level (non-LCD version).

Completely prevents foreign objects from entering and completely prevents dust from entering, capable of withstanding low-pressure water jets from any angle.

- Supports IEC61850 and Modbus communication protocols, enabling communication with the monitoring backend for real-time monitoring of equipment operating conditions.

- A large number of lightweight materials such as aluminum alloy are used to ensure mechanical strength while reducing product size and weight, facilitating on-site installation.

1) Material

- Main body: Anodized aluminum.

- Flange: Anodized aluminum.

- Threaded joint: Stainless steel.

- Glass shell: Tempered safety glass.

2) Operating Environment

- Location: Indoor and outdoor.

- Ambient temperature: -40℃ to +80℃.

-60℃ to +80℃ (polar version).

- Protection level: IP65 (non-LCD version).

3) Silicone Weight

- ITB-100: Approximately 1.6 kg.

- ITB-100T: Approximately 1.6 kg.

- ITB-200T: Approximately 2.8 kg.

- ITB-500T: Approximately 5.6 kg.

4) Device Weight

- ITB-100: Approximately 9.5 kg.

- ITB-100T: Approximately 9.5 kg.

- ITB-200T: Approximately 13 kg.

- ITB-500T: Approximately 25 kg.

5) Electrical Wiring

- Cable joint: 3 x M20x1.5.

- Terminal: 4mm2, AWG24-10 (both soft and hard wires are acceptable).

6) Electrical Performance

- Rated voltage: 85~264V AC, 120~370V DC.

- Rated insulation voltage: 2.0kV 50/60 Hz, 1 minute.

- Power voltage and relay contact to ground: 500 V 50/60 Hz, 1 minute.

7) Communication Interface

- 1 RS485, 1 Ethernet port.

- Communication protocol: Modbus protocol (standard) or IEC61850 protocol (optional).

1) Completely maintenance-free.

- No need to replace silicone.

- No need to clean the oil collection box.

2) Intelligent judgment of transformer breathing status.

The ITB maintenance-free dehumidifier has the function of "intelligent judgment of transformer breathing status." This function ensures that heating can only be activated when the transformer is in exhalation mode. This feature effectively prevents water vapor from entering the transformer during the heating process.

3) Withstands various harsh environments, long lifespan.

- Core components are made of imported industrial-grade components.

- Equipped with a metal filter heating device, it can be used even in extremely cold regions.

- All components are corrosion-resistant and resistant to high and low temperatures; metal parts are made of stainless steel or anodized aluminum alloy materials.

- Lifespan of up to 30 years.

- IP65 protection level (non-LCD version).

4) Data recording function.

Can record the operating status of the dehumidifier and various parameters, such as pipeline air temperature, humidity, and the heating startup status of the dehumidifier.

5) Multiple interfaces and protocols.

- Can provide RS485 interface and Ethernet interface.

- Can be configured with IEC61850 protocol, and protocols can also be customized according to user needs.

6) Extended Functions

This device has reserved expansion input and output modules, which can connect to external sensors to achieve other extended functions.

7) Remote Monitoring

ITB intelligent maintenance-free dehumidifier monitoring software can be provided to monitor the dehumidifier in the control room.

Related Products

Welcome Your Message Consultation